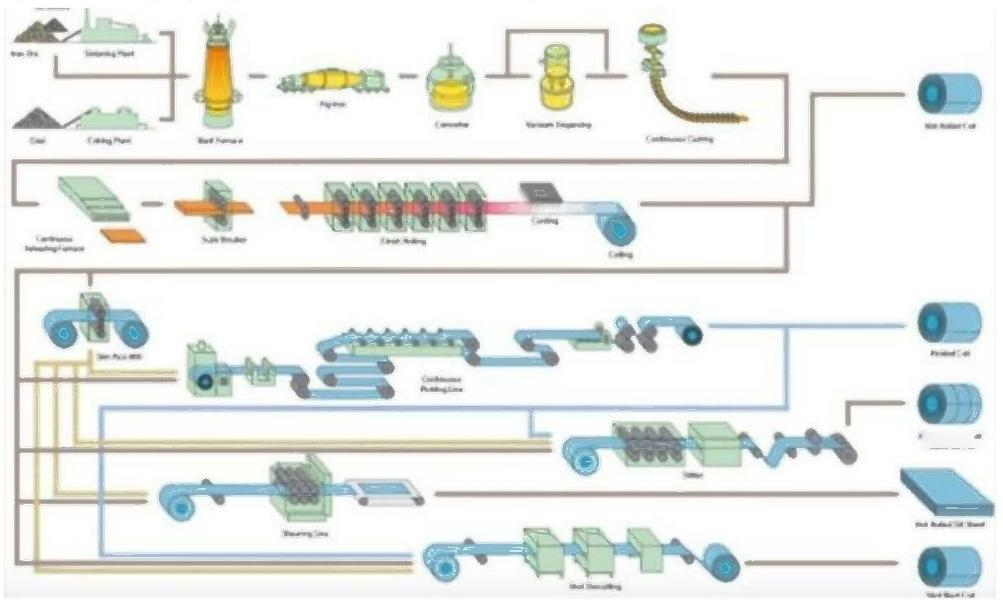

1. Raw material production:

Collect stainless steel scrap,iron,nickel and chromium to manufacturing raw materials

2. Roughing Mill:

The stainless steel slab is then sent back and forth through the Roughing Mill to reduce its thickness and increase its length,without changing its width.

3. Finishing Mill:

Having acquired the shape of a sheet,it is now sent to further thinning in the Finishing Mill depending on customer'requirement.

4. Coiling:

These stainless steel slabs are now turned into plates (-20 mm thickness)or coils(-6 mm thickness)as per order after several intermediate processes.

5. Annealing:

The hot rolled(HR)coil undergoes a thermal process called annealing,in which the metal is given a consistent,uniform internal structure and homogeneous properties.This helps to improve the mechanical stability and corrosion-resistance of the coil

6. Pickling:

The stainless steel coil then goes through a chemical process,Pickling,in which mill scales,surface oxides,and annealing oxides are removed.

7. Quality Testing:

There is quality testing at each stage of production,where a sample is taken from the product,and sent to labs for physical and chemical examination.

8. HRAP/CRAP coils:

The resultant product is called Hot Rolled Annealed Pickled (HRAP)stainless steel coil which goes either directly to the customer,or to be made into.

9. (Customization:

CRAP coil goes through several production processes aimed at custom surface finish,thickness,product chemistry and mechanical properties.Different

kinds of stainless steel finishes such as CR,BA,and 2D/2B are produced during these processes.

10. Slitting:

The stainless steel coils in Cold Rolling Division are reduced to different widths as per the customer requirement.

11. SPD:

For specialized applications and products such as coin blanks,strips for razor blades,and precision strips up to 0.05 mm thickness,our Special Product Division produces highly sophisticated stainless steel products.